A Gear and Timing Belt Assembly

In a previous blog entry, I showed how to make a gear. https://papercraftetc.blogspot.com/2019/05/a-stem-project-how-to-make-gears-using.html I will now explain how to incorporate this gear into a gear and timing belt assembly.

Here is the PDF. I used 20 lb. copy paper for the timing belt and 65 lb. cardstock for everything else.

https://drive.google.com/file/d/192GzmI7ueR99EnuJzDAv-qEA5jDp4-KT/view?usp=sharing

Here is the .Studio file. The instructions for putting the model together follow after the description of how the model was made.

https://drive.google.com/file/d/1oiEHb6rDV3Wngoref_ERLFqdLUcQBRet/view?usp=sharing

Video of the gear and timing belt assembly in action

How the gear and timing belt assembly was made:

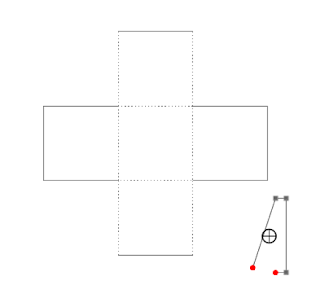

The first thing you need to understand is the shape required to make a timing belt. With this information, the math to determine the circumference of the oval becomes easy to do. The timing belt moves around in an oval shape. This oval shape looks like two circles that are joined by a rectangle. See photo below.

The circumference of this oval is the circumference of one circle (two semicircles make a whole) plus the length of two sides of the rectangle.

The next thing that you need to understand is the make up of the gear. Below is a diagram with three circles circumscribed around a gear. The light blue circle represents the circle needed to make the gear. The dark blue circle represents the location where the timing belt will intersect the gear when it is operating. The green circle represents the outer edge of the gear to determine the distance between the two axles.

In the following text, the colors of the rings correspond to the diameters calculated.

To make the timing belt (dark blue circle), I wanted the distance between each of the gears segments to be one inch. A gear with ten teeth would make a ten inch circumference. Using the circumference formula I can determine its diameter:

C = πd

10 inches = πd

d = 3.183 in.

The diameter of the dark blue circle is 3.183 in. With this measurement, you can now determine the diameters of the other two circles.

The height of the gear tooth is 0.4 in. To determine the diameter of the light blue circle, subtract the height of one gear tooth (the diameter is shortened by 0.2 inches on either side of the dark blue circle). This measurement represents the diameter of the circle needed to make the gear.

3.183 - 0.4 = 2.783 in.

The green circle represents the location of the outer edge of the gear. To determine its diameter, add the height of one gear tooth (the diameter is lengthened by 0.2 inches on either side of the dark blue circle).

3.183 + 0.4 = 3.583 in.

To make a gear, use the diameter measurement of the light blue circle, 2.783 in. and the tooth design included in this file. With the help of the gear making blog entry that I mentioned above, you can recreate the gear that I made.

The spacer prevents the timing belt from shifting around when it is operating. A spacer, before it is constructed, looks like a circle with 10 tabs protruding around its edge. To make one, use the diameter of the timing belt's circle, 3.183 in. and rotate a .45 in. square ten times around the outer edge of this circle. With the help of the gear making blog entry that I mentioned above, you can recreate the spacer that I made.

The outer edge diameter of the gear is 3.583 inches. This value is needed to determine the center location of the two axles. I arbitrarily decided that the distance between the two gears would be 1 inch because I did not want the gears to touch.

3.583 + 1 = 4.583 in. which is the distance between the centers of the two axles

To determine the length of the timing belt use the following formula:

Length of timing belt =

Circumference of the dark blue circle + 2(distance between the two axles)

Length of the timing belt = 10 in. + 2(4.583 in.)

Length of the timing belt = 19.166 in.

(When I made the belt this length - 19.166 in., I determined that I needed a little wiggle room because of the thickness of the paper. I added 0.195 inches to the length and it worked well. I am assuming that this distance was needed to account for the thickness of the paper in all dimensions.)

Length of the timing belt with paper thickness = 19.166 in. + 0.195 = 19.361 in.

To make the timing belt, I needed to determine the size of each square inside the timing belt. I divided 19.361 in. by 19 squares to get 1.019 in. This means that each toothed segment is 1.019 in. wide. I then measured the gear tooth at the location of the timing belt. The gear tooth was 0.357 in. wide. Given that each tooth segment is 1.019 inch wide, I subtracted 0.357 in. to get the distance 0.662 in. between each square.

Using the Silhouette to make the timing belt, I made a template with a square that was 1.019 in. I centered a .357 in. square in the middle. At the bottom edge of the square, I aligned a 1.019 in. dotted line. I then made a rectangle that was 19.361 in. long. I aligned my square template to the the top edge of the 19.361 in. rectangle. I deleted the 1.019 in square and used the replicate function in Silhouette on the 0.357 in. square and the 1.019 in. dotted line to make 18 more segments for the timing belt by using the number of copies custom position window. I made the Y offset 1.019 inch. I added a tab at the bottom of the rectangle by going into point edit mode and adding two points to make a trapezoid. I duplicated this strip and then removed the squares to make two strips, one with 9 squares and the other with 10 squares. I made sure everything remained aligned when I adjusted the strips.

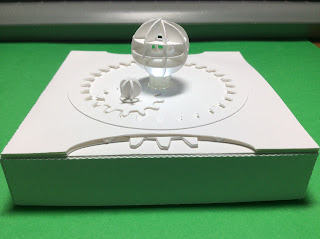

To make the outside casing for the gears, I made a circle that had a diameter of 4.225 in. I determined this value by sight, please note that this diameter is arbitrary. I centered a 0.5 in circle for the axle in the center of this circle.I duplicated this circle within a circle. I made a rectangle with a width of 4.225 and a length of 4.583 which is the distance between the centers of the two axles. I aligned the shapes to look like the first photo above. Using the offset window, I offset the outer edge by .01 inches. I removed the two 4.225 in. circles to make the side of the casing without tabs. I duplicated this casing shape and added two tabs at the top and bottom to make the second side.

I used the improved square axle design from this blog post https://papercraftetc.blogspot.com/2019/06/a-stem-project-making-axle-for-gear.html because I wanted an axle that could withstand a lot of torque.

Instructions on how to put the model together:

When making this model, keep all your pieces stacked up and aligned together when taking them off your Silhouette mat. It makes gluing the gears and spacers easier when everything is already aligned and you do not have to play with them to make sure that the teeth and center square are aligned perfectly. I also recommend using a quilling glue bottle filled with tacky glue. You need small amounts of glue to adhere the pieces for precision gluing.

Using the Silhouette to make the timing belt, I made a template with a square that was 1.019 in. I centered a .357 in. square in the middle. At the bottom edge of the square, I aligned a 1.019 in. dotted line. I then made a rectangle that was 19.361 in. long. I aligned my square template to the the top edge of the 19.361 in. rectangle. I deleted the 1.019 in square and used the replicate function in Silhouette on the 0.357 in. square and the 1.019 in. dotted line to make 18 more segments for the timing belt by using the number of copies custom position window. I made the Y offset 1.019 inch. I added a tab at the bottom of the rectangle by going into point edit mode and adding two points to make a trapezoid. I duplicated this strip and then removed the squares to make two strips, one with 9 squares and the other with 10 squares. I made sure everything remained aligned when I adjusted the strips.

To make the outside casing for the gears, I made a circle that had a diameter of 4.225 in. I determined this value by sight, please note that this diameter is arbitrary. I centered a 0.5 in circle for the axle in the center of this circle.I duplicated this circle within a circle. I made a rectangle with a width of 4.225 and a length of 4.583 which is the distance between the centers of the two axles. I aligned the shapes to look like the first photo above. Using the offset window, I offset the outer edge by .01 inches. I removed the two 4.225 in. circles to make the side of the casing without tabs. I duplicated this casing shape and added two tabs at the top and bottom to make the second side.

I used the improved square axle design from this blog post https://papercraftetc.blogspot.com/2019/06/a-stem-project-making-axle-for-gear.html because I wanted an axle that could withstand a lot of torque.

Instructions on how to put the model together:

When making this model, keep all your pieces stacked up and aligned together when taking them off your Silhouette mat. It makes gluing the gears and spacers easier when everything is already aligned and you do not have to play with them to make sure that the teeth and center square are aligned perfectly. I also recommend using a quilling glue bottle filled with tacky glue. You need small amounts of glue to adhere the pieces for precision gluing.

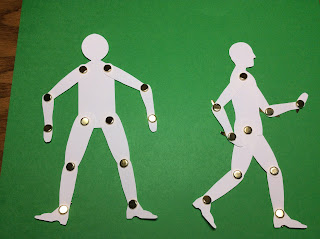

Glue the three chipboard gear pieces together. Make sure that you align the circle and the center square. Repeat for the second gear.

In the picture above on the top left, sandwich the two yellow cardstock pieces on either side of the chipboard on the bottom left with glue. Completed gear is on the bottom right.

Glue the cardstock casing together with the chipboard in the center. Do not apply too much glue to the top and bottom of the casing as this will be pulled apart to put in the tab later.

Glue the cardstock casing to the chipboard. The tabbed cardstock outer casing will be glued on later.

Bend the tabs of the spacers as shown in the photo on above left. Align the center square as shown in the middle of the photo. Glue all of the aligned tabs together. I used tweezers to get the tabs to adhere correctly. Two completed spacers on the top right.

Bend the axle and apply glue as shown. Adhere the axle into a square.

Insert the axle into the square. Glue the tabs down.

The axle should be able to stand up as shown in the photo above. Repeat for the second axle.

Thread the axles through the casing which has its chipboard showing.

Thread a spacer onto each of the axles.

Thread a gear onto each of the axles.

Thread another spacer onto each of the axles.

Glue the two strips of timing belt together precisely.

Thread the timing belt onto the teeth and glue the belt precisely together.

The timing belt and gear assembly should look as shown above.

Make the knobs by sandwiching cardstock, two chipboards and another piece of cardstock together. The gear on the bottom has been glued together.

Thread the casing through the axle. Thread the knob through the axle. Glue the tabs down onto the knob. Add a blue circle to the top of the knob(not shown in photo above).

Glue the casing with the tabs onto the chipboard. Please make sure that you do not apply any glue to the area where the axles reside.

Glue the tabs to the inside of the assembly by pulling apart the glued inner casing. Insert the tab inside the casing so that it does not show. Repeat for the other tab.

Completed Gear and Timing Belt Assembly