When I was a little girl, this was my favorite amusement park ride. This ride spins around an oval track and throws you against the side of the seat when you go around the curve of the oval. It is nice to know that Trimper's Amusement Park in Ocean City, MD still operates this ride so you can experience the fun of this ride.

When operating this whip, both knobs need to be turned simultaneously because equal pressure needs to be applied to both axles. If just one knob is turned, the belt goes out of alignment because this model does not have a top spacer and a casing to keep everything aligned.

Whip Ride in Action

Here is the PDF. I used Silhouette chipboard and 65 lb cardstock for this model.

https://drive.google.com/file/d/1AZe6vHUDugB9_9YCTGYk8v6-33ZGExjm/view?usp=sharing

Here is the .Studio file.

https://drive.google.com/file/d/1Cnh_0DcNyu0DQOzK2UapYsWA71dzm8ZS/view?usp=sharing

Glue the three pieces of the box top sides together. Form into a circle and glue. Repeat for the three sides of the box bottom.

Bend the tabs of the box top and apply glue to each of the tabs. Adhere the inside top of box to the tabs. Repeat for the bottom of the box.

Turn the bottom of the box over and apply glue near the sides of the box bottom. Adhere the bottom of the box to the glue.

Attach the bottom of the box to the top of the box. Set it aside.

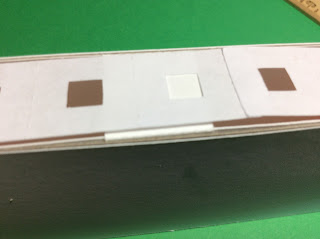

Glue the belt into a circle by gluing the tabs. Precision matters so glue carefully by aligning the paper. The dotted line should be barely seen.

Bend the chair belt assembly as shown above and glue the triangular extensions and the seat platform together.

Repeat for all of the chair belt assemblies.

Glue the chair belt assemblies to the belt. The holes need to be aligned exactly so care is needed when attaching the two belts together,

Repeat for all the chair belt assemblies. Set this aside for now.

Glue the chipboard to the top of the box.

Apply glue to the axles and make them into square axles. See https://papercraftetc.blogspot.com/2019/06/a-stem-project-making-axle-for-gear.html if you are having problems making it.

Glue a base onto the axle and slide through the hole as shown. Repeat for the other axle.

Make the two spacers by aligning the center square and circle. Apply glue to the tabs and adhere them. I used tweezers to help adhere the glue.

Slide the spacers onto the axles.

Completed gear on top was made by placing the pieces in the second row, from left to right, gluing one on top of the other.

Slide the gear onto the axle and thread the belt onto the gears.

Slide the circle with a square in the middle onto the axle and glue the tabs of the axle down onto the circle as shown above. From left to right at the bottom the above photo are the five pieces that need to be glued together to form the knob. Glue the knob to the center of the axle. Repeat for the second knob.

Make the chairs by gluing on the sides.

Bend the chairs upright and apply glue to the inside chair ridges. Bend the seat and adhere the seat to the glue on the chair ridges.

Completed seat on the left.

Glue the seats onto the chair belt assembly. Make sure that the seat is centered on the seat platform.

Apply glue to the top of the box as shown

Adhere the whip assembly onto the top of the box.

Make the embellishments by gluing the strips together. Accuracy matters in gluing these strips. Make sure that the dotted lines are barely showing. Glue the blue starred strip onto the white strip.

Using a glue stick, apply glue to the embellishment and glue onto the white strip. Repeat for all of the embellishments so that it will look like the photo below.

Slide it onto to the top of the box to make sure it will fit correctly.

Embellishment being slid onto the top of the box. Once it looks ok, glue into a circle. Glue the embellishment onto the top of the box.

Inside of the top with the embellishment to show placement.

Completed box.