Colonial Williamsburg Windmill

The Colonial Williamsburg windmill has an interesting history. Check out its history here at the official Colonial Williamsburg website.

https://www.history.org/foundation/journal/autumn02/windmill.cfm

This model is not an exact replica of the windmill. The exterior does not include the stairs or the wheeled tail pole. The inner workings of the windmill are my interpretation of the grinding mechanism due to size and scale.

Video of Windmill Model in Action

Here is the PDF. I used Silhouette chipboard, 120lb. cover stock and 65 lb. cardstock.

https://drive.google.com/file/d/140l3fALZnchGpT_YXD_lV3eguL42xTdp/view?usp=sharing

Here is the .Studio file.

https://drive.google.com/file/d/1offtx0dQ-k5BqFlfGXgSCAsP_3W3ONrU/view?usp=sharing

Fold the corner base pieces and glue the tabs to form a square. Repeat for the other three squares.

Insert the square into the base of the box top. Repeat for the other three squares.

Glue the tabs down. Repeat for the other three squares.

Underside view once completed.

Top view on left. Center beam on right.

Apply glue to the center beam as shown and fold it into a square tube. This center beam was made in a previous blog post. I called it an improved axle. For more information about this improved axle with internal structure, see this blogpost where I made this axle. https://papercraftetc.blogspot.com/2019/06/a-stem-project-making-axle-for-gear.html

Insert the center beam, into the center hole.

Glue down the center beam tabs.

Gather the pieces for the base beams of the windmill as shown above.

Glue each of the pieces into a square. Please note that the tab is smaller in size than the side of the square. Make sure that the glue is placed on the tab.

Glue the three end tabs together. The vertical beam has two ends(right) and the horizontal beam has one end(left). The third piece is the crossbar so it does not have an end (middle piece above).

Looking at the previous picture above. Take the left piece and place it carefully in the bottom hole of the right piece. It is a tight fit. Don't smash the piece in because it will bend. If needed, use a pin to stretch the opening and guide the piece in.

Insert the crossbar into the top hole of the vertical beam. I inserted it on an angle and turned it to align it into place.

Insert the crossbeam into the bottom beam to complete.

After completing all four beams, stack them together to insure that the angles of the beams are the same. I did not glue the beams together.

Apply glue as shown above.

Adhere the cross beams to the center beam of the windmill base.

Adhere the horizontal beam to the middle of the square base as shown above. Repeat gluing for all of the other beams.

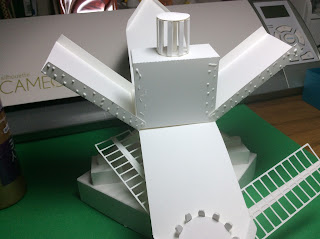

Windmill base. Set aside.

Make the top of the box by folding the sides as shown above.

Glue into a square.

Apply glue to the inside tabs of the box and adhere the inside of the box. Repeat the above three steps for the bottom of the box.

Apply glue as shown above and adhere the bottom of the box. The bottom of the box has two layers of paper to give it support.

Glue the windmill base to the top of the box.

Thread the washer onto the windmill base and set aside.

Layout the four windmill blades

Sandwich the chipboard onto the corresponding cardstock by gluing it together. I like putting the glue on the chipboard side because it absorbs the glue.

Glue the blade frame onto the blade as shown above. Repeat for the other three blades.

Completed blades.

Insert the blade tabs into the blade axle as shown above. Spread the tabs apart and glue to either side. Repeat for the other blades. Please note that the blades are tilted slightly at at 10 degree angle

Back side of blade axle once all of the blades were glued.

Apply glue as shown and bend the tabs inward to create a square axle.

Axle and Blades

Glue the end tab down where there is just two tabs. The four tab end will go into the windmill later.

Bend the tiny squares at a right angle.

Glue the square onto the side of the axle and to the blade frame. This is necessary to give the blade support when rotating. Repeat for all blades.

Turn the blade assembly over and glue the squares to the underside of the blades too. Set this aside.

Bend the center X outward on the one spindle. Make the spindle by bending the spokes and gluing them together. You might need tweezers to adhere the spokes.

Completed Spindle

Bend the center X outward on the one grinding wheel. Make the two grinding wheels by bending up the tabs and gluing them together. Make sure the holes match up so that the tabs are aligned. You might need tweezers to adhere the tabs.

Completed Grinding Wheels

Glue the four gears together. Make sure to apply glue to each of the teeth.

Squeeze the teeth together to make sure that they are bonded and aligned together.

At the circle line of the gear. Bend the teeth inward so that it looks like the above photo.

Make the grinding wheel axle by gluing it and making it into a tube.

Thread a washer onto the axle.

Glue the tabs to the washer.

Bend the tabs of the square grinding floor and thread the grinding axle through the floor as shown above.

Thread a grinding wheel onto the axle and apply glue to the underside where the grinding wheel will sit as shown above. Make sure the axle moves freely and does NOT move the grinding wheel.

Thread the second grinding wheel onto the axle and glue down the four triangular tabs to the grinding wheel axle. Please note that the bottom grinding wheel is stationary and the top grinding wheel rotates with the rotation of the axle.

Bend the shelf as shown above. Apply a drop of glue to make sure the shelf is at a right angle.

Thread the shelf through the grinding wheel axle and apply glue to the floor as shown above.

Grinding Wheel Axle Assembly

Pinch the tabs of the axle together. Thread the spindle onto the axle.

Bend the axle tabs down.

Apply glue to the top of the spindle.

Adhere a circle to the top of the spindle.

Bend the tabs of the windmill washer upward.

Thread the washer onto the windmill axle with the triangles pointing to the windmill blades. Apply a drop of glue to each of the triangles and adhere to the windmill axle.

Bend all the tabs of the windmill house. Thread the house through the center hole. Apply glue to the four center tabs.

Adhere a circle to the center tabs. Make sure the house rotates freely.

Thread the windmill blade axle through the hole in the side. Set the grinding wheel assembly into the house.

Bend the windmill blade tabs down and apply glue to the tabs.

Adhere a circle to the tabs.

Add a second circle to the previous circle. Depending on paper thickness, you might need to apply an additional circle. Glue the gear onto the center of the circle.

Apply glue as shown on the back of the shelf and on the tabs of the house. Adhere the sides of the house.

Apply glue to the shelf sides and adhere to the house.

Glue a coin underneath the floor of the house as a counterweight for the windmill blades.

Apply glue to the sides and floor of the grinding wheel base. Adhere to the house.

Glue on the roof of the windmill.

Grinding mechanism can be seen through the door and the windmill gear can be seen through the hole in the roof.

Completed Colonial Williamsburg Windmill

To move the windmill. With the one hand, hold the windmill steady. With the other hand, use the center axle to move the blades. Moving just one blade will cause the mechanism to go out of alignment.

Ciao from Italy!

ReplyDeleteI love all your projects and I'd like to make them but I don't understand which type of cardstock I must buy.

Living in Italy our method of measuring/measurement is different... please can you help me? Thank you bery much!

1 lb = 16 oz = 453.59237 grams (Convert pounds(lbs) to grams(g))

ReplyDelete